ROPLASS is dedicated to developing value-adding and innovative technologies for surface treatment of polymeric materials used in automotive, textile, films, paper, glass and other industries using atmospheric plasma.

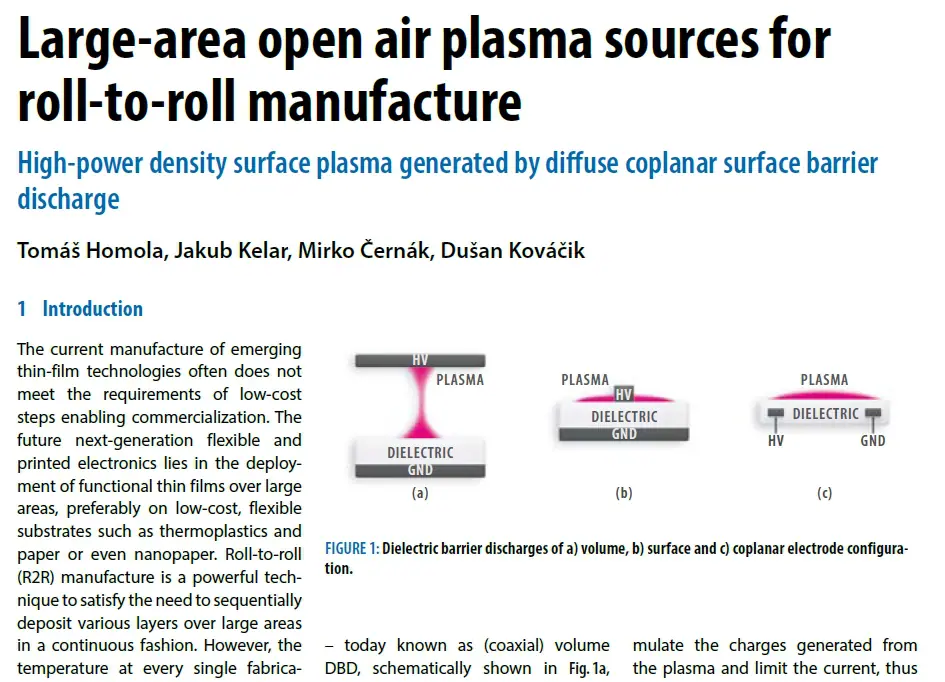

ROPLASS has developed breakthrough technology that creates homogeneous plasma at atmospheric pressure without using noble gases. Our technology is called Diffuse Coplanar Surface Barrier Discharge (DCSBD).

- Why is DCSBD effective without the need for inert gas admixtures (such as helium or argon)?

- What can you treat with our DCSBD – based solutions?

- How can your business benefit from DCSBD technology?

- Why is ROPLASS the right partner for you?

To learn the answers and even more, please click on the links on this page or just